Simplify, Protect, Automate Your Equipment and Machines

In today’s data driven operations where Industry 4.0, digital transformation and the Industrial Internet of Things are fast becoming common initiatives, the need for smart machines and equipment is critical. Manufacturers like you are quickly embarking on digital transformation journeys. They are automating and modernizing their operations – using innovative machines to create smarter factories.

In addition to monitoring and controlling applications, your customers require machines or equipment that enable them to achieve key business results using information or data that is visible and actionable from the edge to the data center and in the Cloud.

Smart Factories are connected, digitalized plants that depend on integrated supply chain solutions, optimized asset performance management, intelligent automation and smart machines.

Smart machine and equipment builders who want to separate themselves from the competition must evolve to achieve digital transformation. Stratus Technologies provides machine builder solutions that enable the Edge Computing you need to succeed in this business evolution. With Stratus platforms, machine and equipment builders have the option to deliver smart machines that are reliable, scalable, accessible, and easy-to-deploy, operate, and maintain, while at the same time provide real-time performance and maintenance data.

Digitalization is not a choice –

Machine builders need to adopt this direction in order to create smart machines

Smart equipment is the foundation of Smart Manufacturing. These machines – equipped with IoT capable sensors, intelligent controllers, and HMI/SCADA systems – take advantage of the innovations in digital technology. Realizing the full benefit of these technologies, while ensuring their safe and reliable operation, requires Edge Computing.

Machine Builders need Edge Computing platforms that meet their unique requirements – and those of their customers.

Look to Stratus to be your Edge Computing partner of choice.

Where is the Edge?

The Edge is the physical location where operations take place; where products are produced; where operational data exists and can be collected and analyzed, allowing for improvements in production. It’s where machines are installed – on the plant floor or production line.

How will Edge Computing extend the capabilities of your equipment?

It enables IIoT solutions and helps gather data from sensors.

It extends control and monitoring beyond traditional displays and into newer devices like smart-phones, tablets, laptops, and command centers.

It avoids problems of latency by collecting and processing information near the process area securely.

It makes information available to the enterprise and the cloud.

Creates the opportunity for value-add services.

Improves reliability allowing for significant leaps in business performance.

The best software is only as good as the infrastructure it runs on.

Why Should Machine Builders Use Edge Computing Platforms?

There are a variety of computing platforms available for machine and equipment builders. The best choice reliably meets the requirements of your customers’ operational environment and are highly-scalable in order to handle the complexity and size of your machine or piece of equipment.

Purpose-built Edge Computing platforms combine powerful computing solutions with inherent redundancy and built-in virtualization that you can embed in your machines. They improve machine monitoring and control, and can be used in a myriad of applications including historian servers and analytics for collecting information from IIoT devices and sensors passing data to the Cloud and the Enterprise.

Most if not all machines have a Programmable Logic Controller (PLC) or a Programmable Automation Controller (PAC) that control inputs and outputs. Despite the hundreds or thousands of operations that can be happening in the PLC every day, the ability to analyze what’s happening is not available on a vast majority of machines. Edge Computing platforms feature a number of benefits in addition to added levels of security and protection.

Introducing IPCs or repurposing general-purpose IT servers as computing platforms in austere, high temperature and high-vibration environments creates unnecessary risk and can undermine the performance of your smart machine. IPCs are industrial grade but do not provide any redundancy, meaning your machine and your customers’ operations will be disrupted by periodic manual interventions. Traditional IT servers typically found in a data center are not industrial grade and need to be housed in environment-controlled locations like server rooms or server farms not conducive to smart manufacturing.

By 2022, more than 50% of industrial IoT analytics will be performed at the edge, up from less than 10% today.

-Gartner

Not all Edge Computing Platforms are Equal

Stratus Technologies offers zero touch Edge Computing Solutions. For decades, we’ve protected our partners and customers from significant financial and reputational risk by securely and reliably delivering information to applications in the cloud and the data center.

Consider the Stratus ztC Edge – the perfect Edge Computing solution designed for Machine Builders

Secure, rugged, highly automated computing solution delivers redundant virtualized industrial applications quickly and easily, improving productivity and reducing risk.

Why should Machine Builders use Stratus?

Your Edge Computing platform should be easy to use, powerful, reliable, and extremely flexible leaving your team to focus on designing, delivering and supporting industry-leading machines.

Here are out-of-the-box benefits Machine and Equipment Builders get from using Stratus Edge Computing platforms:

Simple

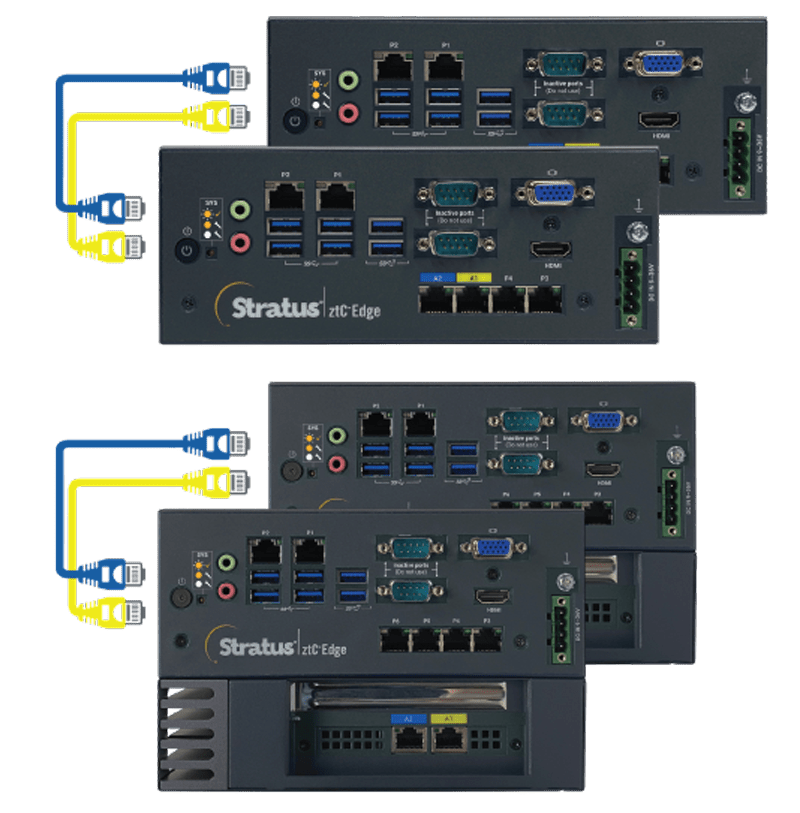

Ease of Management – Our platforms are as easy to manage as unplugging cables and plugging in another node. Resynchronization takes place automatically.

Ease of support – Built-in diagnostics with easy recovery are found in each platform.

Faster commissioning time – The easy-to-set-up and preloaded software allows you to expedite the commissioning of new machines.

Protected

Integrated virtualization and redundancy – Everything is pre-integrated and configured. There are no hardware pairs or clusters that need to be specially cabled together or configured. Stratus platforms are hot-swappable, self-recognizing and auto synchronizing.

Uptime of machines/OEE Improvement – Rugged construction and redundant capabilities increase machine performance and improves your OEE.

Enhanced Security – With our platforms you gain host-based firewalls to blacklist or whitelist, restricted USB ports to help prevent the spread of malware, and a secure boot that prevents cyberattacks.

Industrial Grade – Our compact fan-less configuration can be wall or DIN rail mounted inside your machine control panel, rated at -40 to 60 deg C, 10 to 95% humidity, with 5-500 Hz vibration.

Autonomous

Greater Visibility – With monitoring of SSD, application and guest OS, OPC UA Support you have all the visibility you need into the platform.

Granular access to systems status – We provide applications and virtual machine performance information, CPU usage, memory utilization, and disk space to ensure system status.

System health and support – The system monitors its health 24×7 health conducting predictive failure analysis, automatic updates and patch management, while allowing you to set thresholds, receive alerts and review logs.

What industrial automation vendor do you use in your machines?

Stratus recognizes the importance of your relationships with industrial automation vendors, and we’ve made it a point to be compatible with those brands you rely on. In most cases, we have direct relationships with them to make sure their hardware and/or software is compatible with our Edge Computing platforms.

Edge Computing Success – come and join us

It’s time for you to join our growing list of satisfied customers and partners. Stratus offers zero touch Edge Computing platforms that simplify, protect and automate digitally transforming business-critical operations. For decades, we’ve protected our partners and customers from significant financial and reputational risk by securely and reliably delivering actionable information to applications on site, in the data center, and in the Cloud.

$8.6T transactions

4 of the 5 largest global credit card networks use Stratus solutions.

Fortune 100

Half of the Fortune Global 100 are current Stratus customers.

$843B revenues

Half of the world’s 10 largest retailers are Stratus customers.

200M tons

5 of the world’s 10 largest beverage companies use Stratus solutions.

We extend these benefits to the Edge so Machine Builders can create machines that maximize operational efficiency and improve performance and safety, while minimizing unplanned downtime and cost. Making your business more profitable and your customer’s life easier and more productive.